Optimizing IIoT Networks for Scalable Industrial Automation: A Comprehensive Guide

Estimated reading time: 15 minutes

Key Takeaways

- IIoT networks require specialized design for industrial environments

- Scalability challenges include bandwidth, security, and legacy integration

- Edge computing is essential for managing data flow at scale

- Multiple connectivity technologies address different industrial requirements

- Security protocols must grow alongside network expansion

Table of contents

- Understanding IIoT Fundamentals

- Challenges in Scaling IIoT Networks

- Key Elements of Scalable IIoT Network Architecture

- Edge Computing for IIoT Networks

- Connectivity Technologies for Scalable IIoT Networks

- Security Considerations for Expanding IIoT Networks

- Data Management Strategies for Scalable IIoT Implementation

- Case Studies: Successful IIoT Network Scaling

- Implementation Roadmap

- Future Trends in IIoT Networks for Industrial Automation

- Conclusion

- FAQ

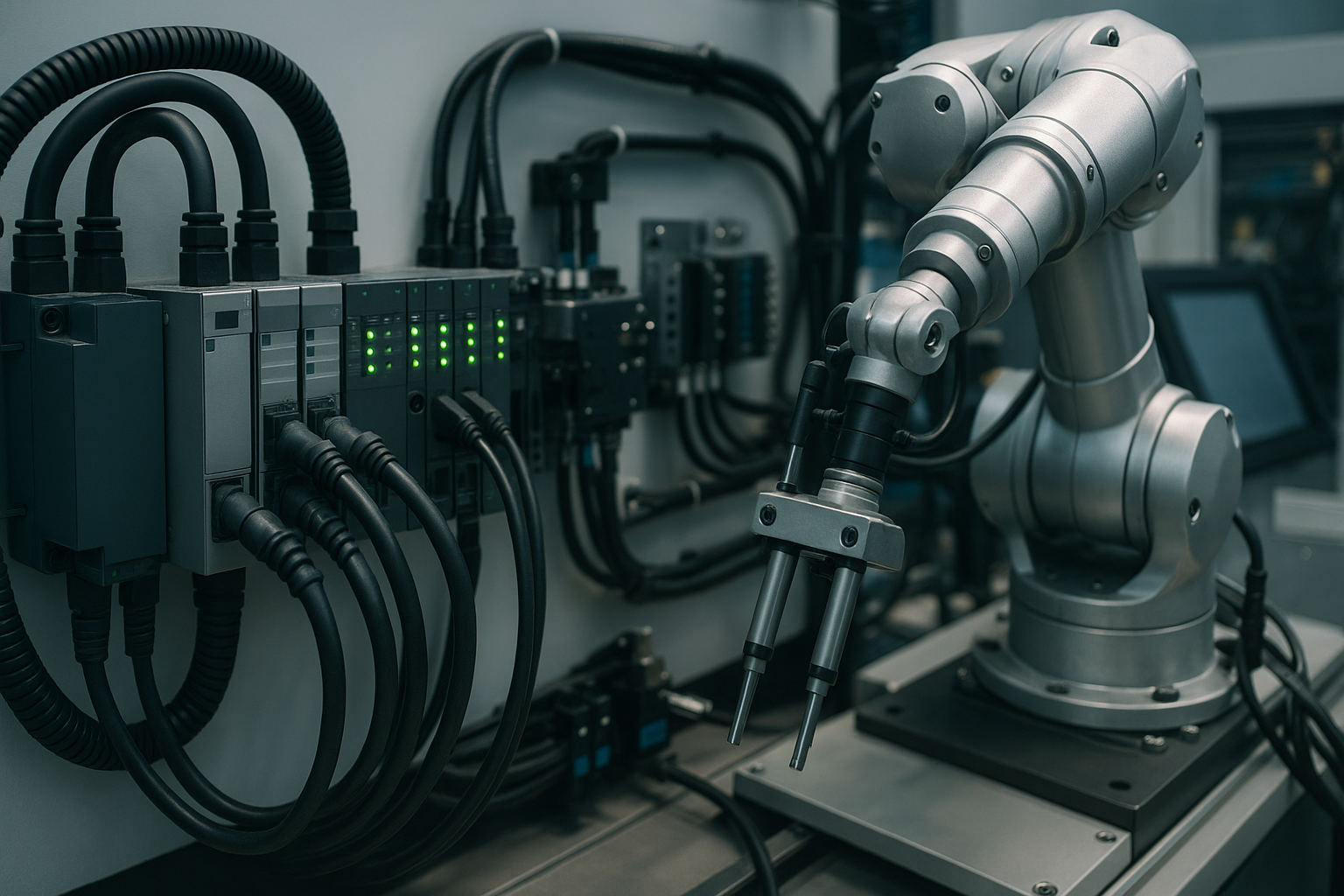

The manufacturing floor of 2023 bears little resemblance to its counterpart from even five years ago. Where isolated machines once operated independently, we now find interconnected systems sharing data in real-time, optimizing processes automatically, and providing unprecedented visibility into operations. This transformation springs from the Industrial Internet of Things (IIoT) – networks of interconnected industrial devices designed to enable data-driven automation and real-time decision-making.

IIoT’s impact on industry has been profound, elevating efficiency and operational visibility while making manufacturing more responsive to changing conditions. But as companies expand their digital initiatives, a critical question emerges: how can these networks scale effectively without compromising performance, security, or reliability?

The answer lies in thoughtful optimization. This article examines strategies for building IIoT networks that don’t just work today but can grow alongside your automation ambitions tomorrow.

Understanding IIoT Fundamentals

IIoT networks operate as complex ecosystems comprising multiple elements:

- Smart sensors capturing physical data

- Gateways managing local device communications

- Connected machines with embedded controllers

- Industrial controllers coordinating automated processes

- Analytics platforms processing operational data

- Software applications providing visualization and control

Unlike traditional IT networks serving office environments, IIoT networks function in challenging industrial settings characterized by extreme temperatures, vibration, dust, and electromagnetic interference. This operational reality creates unique requirements:

- Ultra-low latency for real-time control

- Deterministic data transfer with guaranteed delivery times

- Enhanced physical and cybersecurity protocols

- High reliability even under harsh conditions

These networks enable critical industrial automation initiatives including real-time production monitoring, predictive maintenance, and autonomous manufacturing lines.

Challenges in Scaling IIoT Networks

As organizations expand their IIoT footprint, several challenges emerge:

| Challenge | Description |

|---|---|

| Bandwidth constraints | Data volumes grow exponentially with device count |

| Security vulnerabilities | Attack surface widens with each new endpoint |

| Legacy integration | Older equipment lacks native connectivity |

| Data management | Processing bottlenecks with massive sensor streams |

| Edge limitations | Power and processing constraints at network periphery |

These obstacles can severely hamper automation initiatives if not addressed through proper network design and scaling strategies.

Key Elements of Scalable IIoT Network Architecture

Creating networks that can grow requires attention to several architectural elements:

Flexible Network Topologies

The physical and logical arrangement of your network matters. Mesh topologies provide resilience through multiple connection paths, while star arrangements simplify management. Many industrial environments benefit from hybrid approaches that combine both models.

Industrial Protocols

Communication standards like MQTT offer lightweight messaging ideal for constrained devices, while OPC UA provides semantic interoperability across manufacturers. Modbus remains valuable for legacy integration. Choosing protocols that support your current needs while accommodating future growth is essential.

Standardization

Adopting industry-wide device protocols and data formats simplifies network expansion. When components speak the same language, integrating new assets becomes straightforward rather than a custom engineering project.

Middleware Platforms

These software layers provide abstraction, device management, and data mediation services that harmonize diverse components. A good middleware platform masks underlying complexity and provides unified management as your network grows.

Edge Computing for IIoT Networks

Edge computing—processing data near its source rather than sending everything to a centralized location—has emerged as a critical enabler of scalable IIoT.

By distributing intelligence throughout the network, edge computing:

- Reduces bandwidth consumption by filtering and preprocessing data

- Enables real-time decision making without cloud latency

- Improves reliability by maintaining local functionality during connectivity interruptions

- Decreases cloud computing costs by handling routine processing locally

The optimal approach typically combines edge and cloud computing. Time-sensitive tasks and high-volume data processing occur at the edge, while the cloud handles historical analysis, cross-site coordination, and long-term storage. These distributed intelligent systems often leverage various AI components, including intelligent agents.

Connectivity Technologies for Scalable IIoT Networks

The foundation of any IIoT implementation is reliable connectivity. Multiple technologies serve different requirements:

Industrial Ethernet

These hardened versions of standard Ethernet provide deterministic, high-speed wired connections for critical operations. Protocols like EtherNet/IP, PROFINET, and EtherCAT ensure precise timing needed for motion control and safety applications.

5G Cellular

The latest cellular technology offers high-capacity, low-latency wireless links with network slicing capabilities that can isolate critical industrial traffic. 5G provides flexibility for large-area coverage without extensive wiring.

Wi-Fi 6 and LoRaWAN

These wireless technologies serve different needs—Wi-Fi 6 for high-bandwidth applications within limited areas, and LoRaWAN for low-power, long-range sensor networks that can operate for years on battery power.

For harsh environments, specialized solutions address interference, extended distances, and provide redundancy for mission-critical systems.

Security Considerations for Expanding IIoT Networks

As IIoT networks grow, their security challenges multiply. Key protection strategies include:

- Zero trust architecture – Verifying every user and device regardless of location, eliminating implicit trust

- Network segmentation – Isolating critical systems from general traffic to limit potential breach impacts

- Strong authentication – Implementing mutual device authentication and identity management

- Encryption – Protecting data both in transit and at rest from unauthorized access

- Continuous monitoring – Deploying systems that detect anomalous behavior across expanding networks

These measures must scale alongside your network to maintain protection as the attack surface grows.

Data Management Strategies for Scalable IIoT Implementation

Effective data management becomes increasingly important as networks expand:

Local Filtering and Preprocessing

Not all data needs centralized storage. Edge systems can filter, aggregate, and preprocess information, transmitting only relevant insights to central repositories.

Time-Series Databases

Purpose-built databases designed for industrial telemetry handle high-volume, timestamp-oriented data more efficiently than traditional relational databases.

Data Governance

Formal policies governing data lifecycle management—from creation through archiving or deletion—ensure compliance and efficient resource utilization at scale.

Standardized Data Models

Common information models promote interoperability between systems and streamline analytics as deployments grow.

Case Studies: Successful IIoT Network Scaling

Examining real-world implementations provides valuable insights:

Siemens leveraged IIoT and digital twin technologies to create virtual representations of physical manufacturing sites. By feeding real-time sensor data into these digital environments, they optimized assembly processes and maintenance procedures across multiple facilities. The scalable architecture allowed them to replicate successful approaches from pilot sites to global operations.

Other industry leaders have combined modular network designs, advanced edge analytics, and comprehensive security measures to support rapid IIoT scaling. These implementations typically yield quantifiable benefits:

- 15-30% reduction in unplanned downtime

- 10-25% improvement in operational efficiency

- Increased production flexibility to accommodate changing market demands

Many organizations have implemented engineering workflow optimizations alongside their IIoT initiatives to maximize productivity gains.

Implementation Roadmap

Organizations seeking to build scalable IIoT networks should follow a structured approach:

- Assessment: Evaluate existing network capabilities, device inventory, and connectivity requirements

- Planning: Develop detailed capacity models accounting for data volume growth, future device additions, and evolving use cases

- Pilot Testing: Implement small-scale deployments to validate design assumptions and identify unexpected challenges. For detailed guidance on testing connected devices, refer to IoT prototyping and device testing guide

- Phased Rollout: Expand gradually with careful monitoring at each stage

- Organizational Change: Develop team skills and establish clear responsibilities for maintaining expanding networks

This methodical process reduces risk while allowing organizations to learn and adjust as they scale.

Future Trends in IIoT Networks for Industrial Automation

Several emerging trends will shape tomorrow’s IIoT networks:

- Advanced Edge Computing: More capable edge devices will support sophisticated AI processing at the network periphery, often leveraging multi-agent systems for distributed intelligence.

- IT/OT Convergence: Traditional information technology and operational technology teams will increasingly merge, creating unified approaches to industrial networking

- AI Integration: Machine learning will enable more autonomous operation and predictive capabilities throughout industrial systems. These developments are part of broader AI trends shaping the future of technology.

- Sustainability Focus: Green networking approaches will reduce energy consumption while maintaining performance, contributing to broader sustainability initiatives across industries.

These developments will further enhance the scalability and capability of industrial automation systems.

Conclusion

Optimizing IIoT networks for scalability requires a holistic approach combining robust architecture, appropriate connectivity technologies, comprehensive security measures, and effective data management. Organizations that master these elements can build automation infrastructure capable of growing alongside their business needs.

For those beginning their IIoT journey, three priorities stand out:

- Invest in network standardization to simplify future expansion

- Implement strong security frameworks from the outset

- Deploy edge computing infrastructure that can grow incrementally

These foundational elements create the flexibility and resilience needed for long-term success in industrial automation. By addressing both immediate needs and future scalability, manufacturers can build systems that deliver competitive advantages today while adapting to tomorrow’s requirements.

FAQ

Q1: What makes IIoT networks different from standard IT networks?

A1: IIoT networks operate in harsh industrial environments, require deterministic performance with ultra-low latency, and connect specialized industrial equipment. They prioritize reliability and real-time operation over the convenience features of standard IT networks.

Q2: How does edge computing benefit IIoT scalability?

A2: Edge computing reduces bandwidth requirements by processing data locally, enables real-time decision making without cloud latency, improves reliability during connectivity issues, and significantly decreases cloud computing costs for large-scale deployments.

Q3: What security measures are most important when scaling IIoT networks?

A3: Critical security measures include zero trust architecture, network segmentation, strong authentication protocols, comprehensive data encryption, and continuous monitoring systems that can detect anomalies across the expanding network.

Q4: Which connectivity technologies work best for large-scale industrial deployments?

A4: The optimal connectivity mix depends on specific requirements. Industrial Ethernet provides deterministic performance for critical operations, 5G offers flexibility for large areas, and technologies like LoRaWAN efficiently connect low-power sensors across extended distances.

Q5: How should companies approach IIoT implementation?

A5: Start with thorough assessment and planning, then implement small pilot projects to validate designs before proceeding to phased deployment. Develop team skills and clear operational responsibilities in parallel with technical implementation.