How 3D Printing Is Transforming Mechanical Engineering Design

Estimated reading time: 12 minutes

Key Takeaways

- 3D printing enables unprecedented geometric freedom in mechanical design

- Part consolidation reduces assembly complexity and improves reliability

- Design for Additive Manufacturing (DFAM) requires new engineering approaches

- Material options have expanded to include high-performance polymers, metals, and ceramics

- Economic benefits include no tooling costs and viable low-volume production

Table of contents

3D printing mechanical engineering is radically reshaping how engineers approach design challenges. The layer-by-layer fabrication process is breaking traditional manufacturing constraints, enabling unprecedented geometric freedom, and changing how we think about part production. This transformation spans from prototyping to full-scale production across aerospace, automotive, and healthcare industries.

While many use “3D printing” and “additive manufacturing” interchangeably, it’s worth noting that industry standards bodies like ASTM and ISO typically use “additive manufacturing” in formal contexts. Engineers need fluency in both terminologies to navigate this evolving landscape.

The Fundamental Shift

Traditional manufacturing methods like milling and drilling are subtractive – they remove material to create the final shape. 3D printing does the opposite, building parts layer by layer from digital models. This fundamental difference unlocks new design possibilities that were previously impossible or cost-prohibitive.

The evolution from rapid prototyping to end-use manufacturing represents one of the most significant shifts in production technology of the past century.

The technology has evolved dramatically from its 1980s origins as a prototyping tool. Today, 3D printing produces end-use components that meet rigorous performance standards across critical industries.

How Design Rules Are Being Rewritten

Design Freedom

Engineers can now create internal channels, complex lattices, and organically optimized structures that would be impossible with conventional methods. The old design rule “complexity costs more” is being replaced by additive manufacturing’s principle of “complexity for free”.

Part Consolidation

Perhaps the most transformative capability is consolidating entire assemblies into single printed components. GE’s famous jet engine fuel nozzle exemplifies this approach – what was once an assembly of 20 separate parts became a single, more reliable printed component.

Lightweighting

Topology optimization algorithms can now determine the ideal material distribution for maximum strength and minimum weight. This is transforming weight-sensitive applications in aerospace and automotive sectors where every gram matters.

Mass Customization

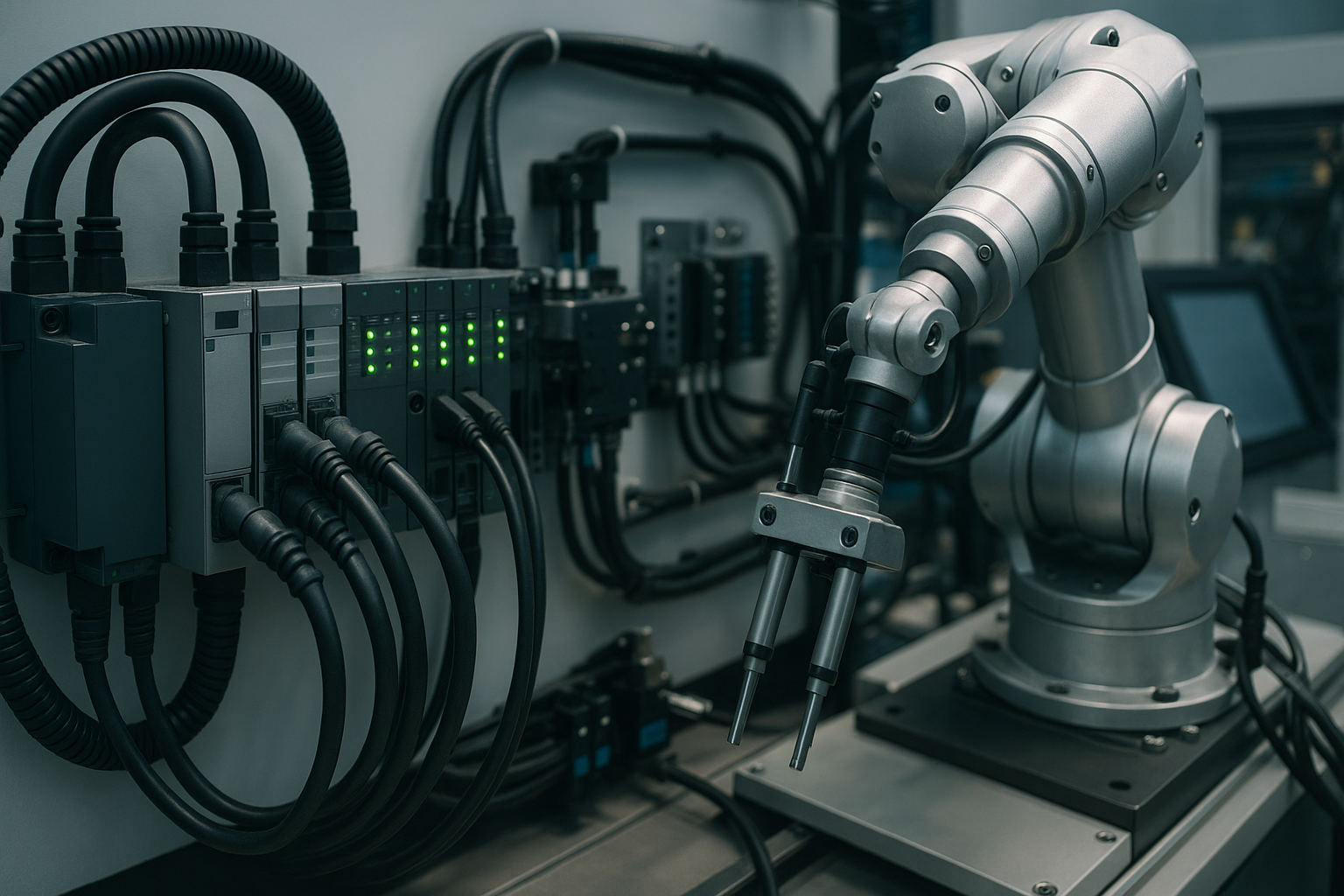

The digital nature of 3D printing enables cost-effective customization. From medical implants tailored to patient anatomy to custom robotics grippers designed for specific parts, additive manufacturing makes mass customization economically viable.

Process Selection Guide for Mechanical Engineers

Selecting the right 3D printing process is critical for success. Each has distinct capabilities and limitations:

| Process | Materials | Best For | Limitations |

|---|---|---|---|

| FDM/FFF | Thermoplastics | Rapid prototyping, large parts | Lower resolution, visible layer lines |

| SLA/DLP | Photopolymers | High detail, smooth surfaces | More brittle materials |

| SLS/MJF | Nylon, polymers | Functional parts, no supports needed | Rougher surface finish |

| DMLS/SLM | Metals (titanium, steel, aluminum) | End-use metal parts | Expensive, requires support structures |

The decision involves balancing requirements for mechanical performance, surface finish, dimensional accuracy, and cost.

Materials Evolution

Material options have expanded dramatically, with properties increasingly matching or exceeding traditional manufacturing:

- Polymers: From basic ABS to high-performance materials like PEEK and carbon-fiber reinforced nylons

- Metals: Aluminum alloys, titanium, stainless steels, and superalloys like Inconel

- Ceramics: Zirconia and alumina for high-temperature applications

Engineers must consider that printed materials often exhibit anisotropic properties – their strength varies depending on build direction. This directional strength must be accounted for in design.

Design for Additive Manufacturing (DFAM)

DFAM represents a mindset shift from traditional Design for Manufacturing. Key principles include:

- Minimum wall thickness: Varies by process but typically 0.5-2mm

- Support structures: Design to minimize supports or make them easy to remove

- Build orientation: Optimize for strength in critical directions

- Internal structures: Lattices can replace solid volumes for weight reduction

- Tolerances: Account for process capabilities (typically ±0.1mm for polymers, ±0.05mm for metals)

Digital Workflow Integration

The 3D printing workflow is inherently digital, spanning from CAD to final production:

- Design: Create parts in CAD software

- Optimization: Apply topology optimization and simulation tools

- Preparation: Orient parts and generate supports

- Slicing: Convert 3D models to layer-by-layer instructions

- Production: Print the physical part

- Post-processing: Remove supports, heat treat, machine critical surfaces

Simulation tools like Ansys and nTopology enable engineers to predict and optimize part performance before production, reducing development cycles.

Real-World Applications

Aerospace

The aerospace industry was an early adopter of metal 3D printing for both weight reduction and supply chain simplification. GE Aviation’s fuel nozzle exemplifies both benefits – 25% lighter than its predecessor while consolidating 20 parts into one.

Automotive

Formula 1 teams leverage 3D printing for rapid iteration of complex components. Production vehicles increasingly feature printed components in low-volume, high-complexity applications.

Medical Devices

Patient-specific implants and surgical guides are transforming healthcare outcomes. The ability to match human anatomy exactly improves surgical success rates and recovery times.

Tooling and Fixtures

Beyond end-use parts, 3D printing excels at creating manufacturing aids like jigs, fixtures, and injection mold inserts with conformal cooling channels that improve cycle times.

Economic Considerations

The economics of 3D printing differ fundamentally from traditional manufacturing:

Sustainable engineering.

- No tooling costs: Eliminating molds and fixtures reduces upfront investment

- Complexity doesn’t increase cost: Intricate parts cost the same as simple ones

- Break-even point: Generally favorable for volumes under 5,000-10,000 units

- Lead time reduction: Parts can be produced in hours or days, not weeks

In traditional manufacturing, complexity is expensive. In additive manufacturing, complexity is free.

This economic model particularly benefits low-volume, high-mix production scenarios.

Future of 3D printing.

Current Limitations

Despite rapid advances, engineers should be aware of current constraints:

- Build volume: Most industrial systems limited to ~450mm in any dimension

- Surface finish: Often requires post-processing for critical surfaces

- Production speed: Still slower than high-volume traditional methods

- Material properties: May exhibit anisotropy or require post-processing to reach full strength

- Quality assurance: In-process monitoring still developing for critical applications

Future Directions

The technology continues to evolve rapidly in several key directions:

- Multi-material printing: Combining different materials in a single build

- AI-driven design: Generative algorithms creating optimized structures beyond human intuition

AI trends - In-situ monitoring: Real-time quality verification during builds

- Distributed manufacturing: On-demand production closer to point of use

Multi-agent systems - Material development: Expanding property ranges and application possibilities

These advances will further expand 3D printing’s role in mechanical engineering.

3D printing trends in 2025.

Getting Started

Engineers looking to incorporate 3D printing into their workflow should:

- Start with prototyping: Build experience before moving to end-use parts

- Learn DFAM principles: Understand how design must adapt to the process

- Partner with experts: Work with service bureaus before investing in equipment

- Stay current: The field evolves rapidly; continuous education is essential

Conclusion

3D printing is transforming mechanical engineering design from a constraint-driven process to a possibility-driven one. The technology enables engineers to optimize for performance rather than manufacturability, creating parts that were previously impossible.

As material capabilities expand and costs continue to decrease, 3D printing will increasingly move from specialized applications to mainstream production. Engineers who master these technologies and design principles will be positioned to create the next generation of mechanical systems that are lighter, more efficient, and better performing than their predecessors.

The question for mechanical engineers is no longer if 3D printing will impact their field, but how quickly they can adapt their design thinking to leverage its transformative capabilities.

FAQ

Q1: What is the difference between 3D printing and additive manufacturing?

A1: While often used interchangeably, “3D printing” typically refers to the general technology, while “additive manufacturing” is the industry-standard term preferred by organizations like ASTM and ISO for formal contexts.

Q2: Which 3D printing technology is best for functional mechanical parts?

A2: For polymer parts, SLS (Selective Laser Sintering) often provides the best combination of mechanical properties and accuracy. For metal components, DMLS (Direct Metal Laser Sintering) or SLM (Selective Laser Melting) are the primary industrial choices.

Q3: How does design for additive manufacturing differ from traditional design?

A3: DFAM emphasizes designing for performance rather than manufacturability. It allows for complex geometries, internal features, and part consolidation that would be impossible with traditional manufacturing methods.

Q4: When is 3D printing economically viable for production?

A4: 3D printing is generally most economical for low to medium production volumes (under 10,000 units), parts with complex geometries, customized components, and situations where tooling costs would be prohibitive.

Q5: What post-processing is typically required for 3D printed parts?

A5: Common post-processing includes support removal, surface finishing (sanding, polishing, media blasting), heat treatment for stress relief, machining of critical dimensions, and sometimes coating or impregnation for improved properties.