Key Takeaways

- Integrate Systems: Overcome the IT/OT divide by using middleware like OPC UA and MQTT, edge gateways for protocol translation, and a Unified Namespace to map legacy systems without a full rip-and-replace.

- Master Data Intelligence: Avoid data overload by starting with a specific business question, filtering data at the edge to reduce noise, and proving value with a single, high-impact use case like predictive maintenance first.

- Build in Security: Shift security from an afterthought to a core part of your architecture with a Zero Trust model, including device-level security, network segmentation, and continuous real-time monitoring.

- Bridge the People Gap: The biggest challenge is often cultural. Foster collaboration by creating cross-functional teams, upskilling both OT and IT staff, and celebrating small, tangible wins to build trust in new systems.

- Plan for Scale: Move beyond “pilot purgatory” by designing for production from day one with a standardized, platform-based architecture, rather than creating bespoke one-offs that are difficult to scale.

Table of Contents

The Promise and the Peril

Smart manufacturing sounds amazing on paper. You wire up machines, stream data, and print money. Then the first week hits and you run smack into legacy systems, weird device quirks, and meetings that never end.

So let’s keep it real. A lot of IIoT implementation work stalls for predictable reasons. The good news is you can start overcoming IIoT challenges with a few tight moves and a clear plan.

The Direct Answer

Here’s the short list we’re going to fix today: legacy system integration, the data overload mess, IoT security across a bigger attack surface, the skills and culture gap, and scaling from pilot to production without burning cash.

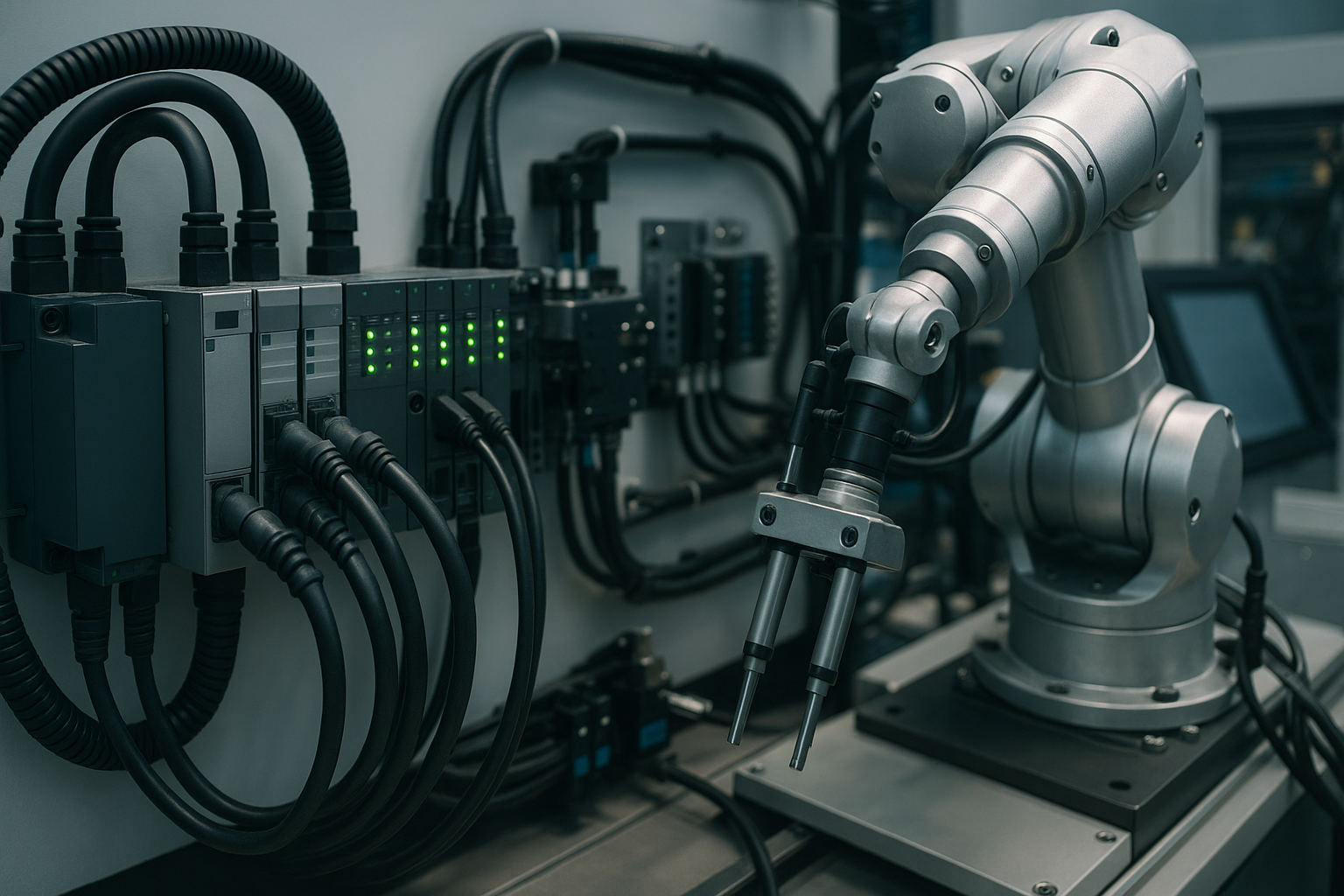

The Integration Impasse: Bridging OT and IT

The hard part usually isn’t the shiny new sensor. It’s getting your new stack to speak to 10 or 20 older systems on the floor that do not want to talk to each other.

In 2025 surveys, 59% said data lives in silos and only 32% said their operational datasets are truly unified. And yes, the OT world likes predictable cycles while IT moves fast and changes often. That clash shows up every single day.

Solutions for Bridging the Divide

- Use middleware that speaks OPC UA and MQTT so your MES, ERP, and PLCs stop acting like strangers

- Drop in edge gateways to translate protocols near the machine for clean, real time signals

- Wrap your brownfield systems instead of ripping them out, then layer a Unified Namespace to map 100s or even 1,000s of tags in one place

- Pace the work, one system per sprint, so your team can ship wins every 2 to 4 weeks

Tip: If you’re serious about overcoming IIoT challenges, start the UNS design early, not after month 6.

The Data Deluge and The Analysis Paralysis

You don’t have a data problem. You have a decision problem. Plants are throwing off 1.2 terabytes a day on a large line. Meanwhile, storage bills rise 15 to 30% year over year and no one can find the few signals that matter.

So what happens next? Teams drown in noise. Alerts fire all day. Nobody trusts the dashboards because the questions weren’t clear up front. That’s how data overload kills momentum.

From Data Collection to Data Intelligence

- Start with the business question, not the sensor, and set the KPI before you turn anything on

- Push analytics to the edge to filter junk and cut cloud bandwidth by 65% or more

- Pick one use case, like predictive maintenance for a single asset class, then prove it with downtime cut by up to 45%

- Set latency budgets. If a step needs under 200 ms and cloud averages 300 ms, keep the loop at the edge and target under 50 ms

Because overcoming IIoT challenges means you pick fewer streams, get cleaner data, and make faster calls.

Security: From Afterthought to Architectural Pillar

In manufacturing IoT, a breach doesn’t just hit a spreadsheet. It can halt a line, scrap expensive parts, or risk worker safety. That’s a different level of risk than your average office app.

Attacks jumped 37% year over year in 2024. And 74% of manufacturing tech leaders ranked security as the top issue. One breach averages about 1.6 million dollars before you even count reputation hits.

A Zero Trust Security Framework for Manufacturing IoT

- Device security first with secure elements and authenticated boot, then TLS everywhere

- Segment the network with VLANs and firewalls so OT stays isolated from corporate IT and the open internet

- Monitor continuously and flag anomalies in real time, not after a weekly report

- Require MFA for remote access and update firmware quarterly across 100% of devices

- Run red team style audits twice a year to prove your controls work

If you care about overcoming IIoT challenges, you bake security into the plan on day one, not month twelve.

The People Problem: Bridging the Skills and Culture Gap

Here’s the part no one wants to admit. Tech is rarely the blocker. People are. On one side you have OT veterans who know the line by sound and smell. On the other, data folks who trust the model. Both are right, and both need each other.

So when the first model says a spindle is fine but the operator hears a new rattle, trust and process decide what you do next. That’s culture. And there’s a real shortage of people who speak both worlds well.

Fostering an IIoT Ready Culture

- Stand up cross functional squads for every project with OT, IT, networking, and safety in the same room

- Upskill OT teams on data basics. Then upskill data teams on the process and cycle times

- Publish a simple playbook so pilots don’t get reinvented line by line

- Celebrate quick wins. A 10% throughput bump on one cell this quarter beats a perfect slide deck

- Tie incentives to KPIs the floor actually cares about like first pass yield and mean time to repair

Because overcoming IIoT challenges is mostly about people trusting the new loop as much as they trust their own eyes.

The Pilot Purgatory: Scaling Beyond the Lab

A cool pilot is not a scalable system. Only 41% of 2024 pilots made it to full production. And leaders still expect payback in under 12 months, even though median ROI lands between 18 and 24 months. That mismatch kills good programs.

Pilots stall when teams build bespoke one offs, underestimate bandwidth and compute, or skip a standard platform. Then they try to copy paste and the wheels fall off.

Pilot Mindset vs. Production Mindset

| Aspect | Pilot | Production |

|---|---|---|

| Goal | Proving a concept | Driving enterprise ROI |

| Tech | Custom or bespoke | Standardized and repeatable |

| Architecture | Ad hoc | Platform based and scalable |

| Support | A small project crew | Dedicated ops and security teams |

Now plan for scale. Upgrade 10 to 25% of machines each quarter instead of trying to flip the whole plant. Use high density WiFi at 5 GHz with enough access points to hold 99.9% uptime on the floor. For wide sites, run fiber to tie buildings together across miles. And because the 2024 chip shortage pushed hardware costs up to 23%, lock in supply early and test devices before you roll wide.

Edge computing helps here too. Keep control loops on site to hit under 50 ms where needed, then push summarized data to the cloud. That move alone clears bottlenecks and makes overcoming IIoT challenges less scary.

Conclusion: From Overcoming Problems to Building Advantage

Don’t treat these five items like a wall. Treat them like a plan. Integration gets easier when you bridge systems instead of replacing them. Data gets useful when you start with the question. Security keeps you safe when it’s built in from the start. People get on board when you upskill both sides and prove small wins. And scale happens when you design for it on day one.

If you commit to overcoming IIoT challenges with that mindset, you give your team a straight shot to a resilient, efficient, and competitive smart manufacturing operation. That’s the move that pays off in 2025, 2026, and beyond.