Key Takeaways

- Physical Layer: This is the foundation where devices like sensors and actuators interact with the physical world, creating and acting on data.

- Connectivity Layer: A mix of network protocols (MQTT, OPC-UA) and types (Wi-Fi, 5G, LPWAN) move raw data from the edge to the cloud.

- Edge Layer: Crucial for real-time decisions, this layer filters and analyzes data locally to reduce latency, save bandwidth, and ensure uptime.

- Processing & Abstraction: Data is sent to a central location (like a data lake) for heavy analysis, and then normalized into a common format for easy use.

- Application Layer: Software uses the processed data for tangible outcomes like predictive maintenance dashboards, remote control interfaces, and process optimization.

- Business Layer: This top layer integrates IIoT insights into enterprise systems like ERP and MES, connecting data to revenue and operational planning.

- Security Mandate: Security is a critical concern that must be integrated across all seven layers, from secure boot at the device level to access control in the cloud.

Table of Contents

Introduction

It’s easy to get a bit lost in the buzz around the Industrial Internet of Things, or IIoT. The idea of connecting every piece of machinery in a factory or on a farm to the internet sounds incredibly powerful, and it is. But it’s also incredibly complex. You’re not just plugging in a sensor; you’re building a bridge between the physical world of heavy machinery and the digital world of cloud software.

Here’s the thing, though. When you look at it the right way, that complexity starts to make a lot of sense. Instead of a tangled mess of wires and code, you can see a logical structure. Most people in the field think about this structure as a stack of different IIoT architecture layers. While some models propose a simplified three-layer architecture, breaking it down into seven key layers helps you understand how data moves, where different technologies fit, and how to design a system that actually works. Let’s walk through the seven key layers that make up a typical, modern IIoT stack.

1. The Physical Substrate: Where Data Is Born

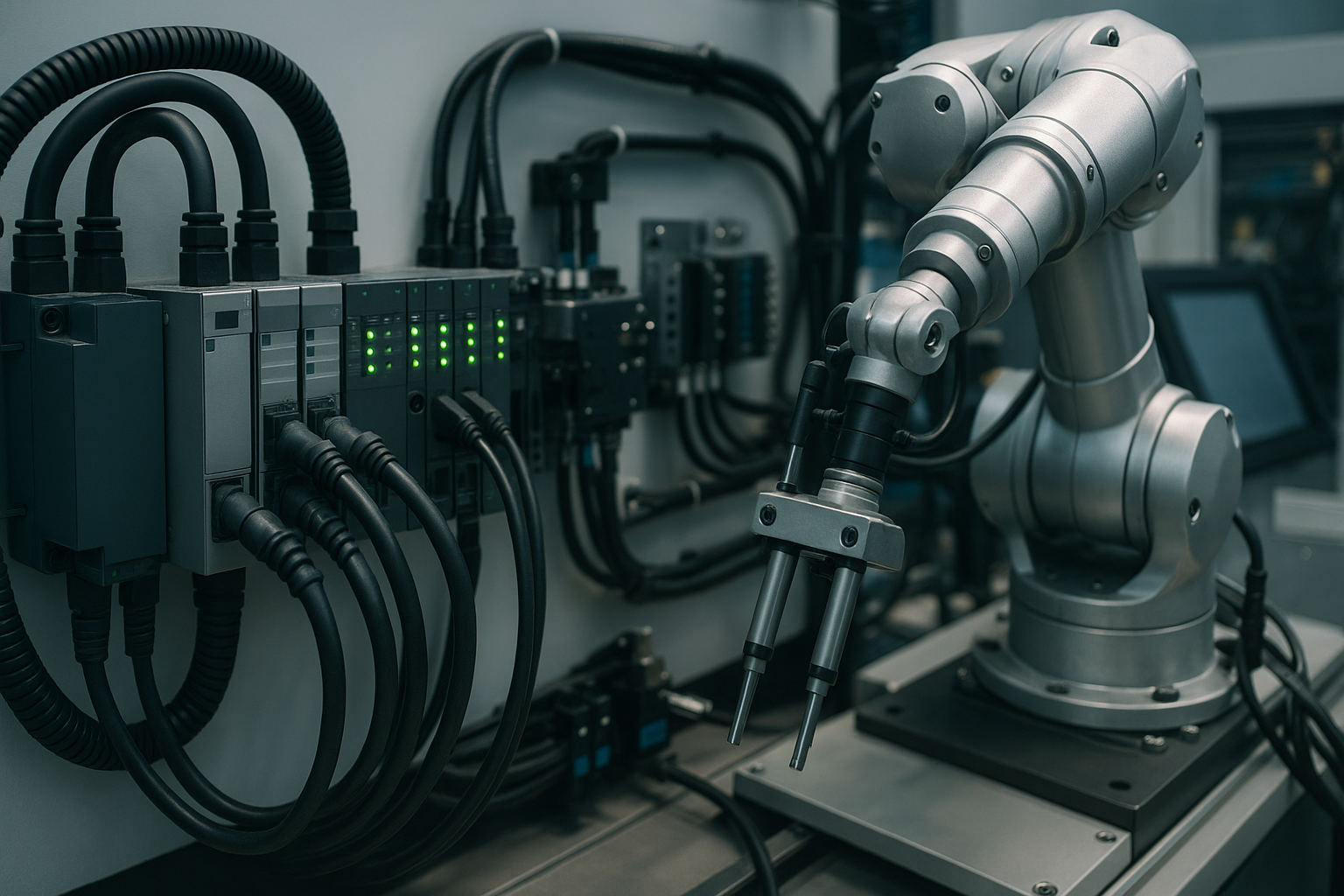

This is the foundation; it’s where physical machines and their environments are sensed, measured, and controlled.

Think of this layer as the system’s sensory organs. It’s all about turning physical reality into digital signals and, sometimes, turning digital commands back into physical action.

- Sensors & Devices: These are the workhorses. They measure physical properties like temperature, pressure, vibration, and location. We’re talking about everything from tiny temperature sensors that might generate just a kilobyte of data per reading to complex vision systems. An average industrial facility might have anywhere from a few hundred to over 10,000 of these sensors. This layer also includes the “things” that do the work, like PLCs (Programmable Logic Controllers) and actuators that open valves or move robotic arms. A good chunk of these, around 45% of new industrial sensors, are now “smart,” meaning they have self-identification features built in.

- Function: The core job here is simple: sensor integration. It’s the direct interface with the real world, capturing raw data right at the source.

A pretty common challenge at this layer is just the environment itself. These devices often have to survive in harsh conditions with extreme temperatures, vibrations, or limited power, all while reliably collecting accurate data.

2. The Connectivity Fabric: The Data Superhighway

This layer is the network infrastructure that reliably moves all that raw data from the physical layer up the stack.

Once you have the data, you need to get it somewhere. This layer is the combination of hardware and software that makes that happen.

- Data Acquisition Systems (DAS): These systems are often the first stop for sensor data. They collect signals from multiple sensors, convert them from analog to digital if needed, and prepare them for transmission across the network.

- Network Protocols: You can’t just send data without a set of rules. This is where IoT communication protocols come in. You’ll see a mix of them depending on the job. MQTT is popular because it’s lightweight, CoAP is designed for low-power devices, and OPC-UA provides a secure, structured way for industrial equipment to talk.

- Network Types: There’s no single network to rule them all. An IIoT system might use a combination of Wi-Fi for local high-speed data, cellular like 4G or 5G for remote assets, Low-Power Wide-Area Networks (LPWAN) for small data packets over long distances, and traditional wired industrial ethernet for reliability.

The key decision here is always a trade-off. You have to pick the right mix of protocols and networks based on what you need for bandwidth, how quickly you need the data (latency), and how much power your devices can spare.

3. The Edge Imperative: Thinking on Your Feet

The edge layer is a crucial point for pre-processing, filtering, and analyzing data locally, right near the source, before sending it on.

It used to be that all data went straight to a central server or the cloud. We quickly learned that’s not always a great idea. Sending terabytes of raw data can get expensive and slow. The edge is the solution.

- Core Functions: Edge devices are responsible for data filtering (we don’t need a temperature reading every millisecond), aggregation (what’s the average pressure over the last 10 seconds?), and even real-time analytics for quick decisions.

- Why It’s an “Imperative”: There are a few big reasons why edge computing is used in around 75% of new IIoT installations today. It dramatically reduces latency, lowers data transmission costs by sending only what’s important, and allows a system to keep running even if its connection to the cloud goes down.

- Key Hardware: The brain of this layer is typically an Edge Gateway or a dedicated edge computing device. These are small, powerful computers that sit between the sensors and the wider network.

For example, an edge device connected to a large motor could analyze vibration data in milliseconds. If it detects a pattern that signals an imminent failure, it can trigger an immediate shutdown order without ever having to ask the cloud for permission.

4. The Data Processing Layer: The Central Brain

This is the layer where processed data is sent to a central location, usually the cloud, for large-scale storage and deep analysis.

While the edge handles the immediate thinking, this is where the heavy-duty number crunching happens. A single industrial facility can generate up to 2 terabytes of data every single day, and this is where it all lands. Big data platforms and AI/ML algorithms churn through this information to find patterns that a local edge device might miss. This is where you move from “real-time” analysis that takes less than a second to “batch” processing that might run for an hour to find long-term trends.

IIoT Architecture Table

| Layer # | Layer Name | Core Function | Example Technologies |

|---|---|---|---|

| 1 | Perception | Sense and control the physical world | Smart sensors, RFID, PLCs, actuators |

| 2 | Connectivity | Move data from devices into the network | Ethernet, Wi Fi, 4G, 5G, LPWAN, MQTT, OPC UA |

| 3 | Edge Computing | Local filter and fast analytics | Edge Gateway, microservers, containers |

| 4 | Data Processing | Store and analyze at scale | Data lake, stream processing, AI and ML |

| 5 | Platform | Manage devices, data, and deployments | IIoT platform, fleet manager, time series DB |

| 6 | Application | Use data for monitoring and control | Dashboards, alerts, predictive maintenance |

| 7 | Business | Tie outcomes to planning and revenue | ERP, MES, BI, reporting and workflows |

5. The Abstraction Engine: Creating a Common Language

This layer standardizes, normalizes, and puts all the diverse data formats into context so they are actually usable.

Let’s be honest, data arriving from the field is a mess. One sensor might send temperature in Celsius every second, while another sends pressure in PSI every five seconds, and a third sends a simple on/off status. The abstraction layer solves this.

- The Problem: Data comes from thousands of different devices, in different formats, on different timetables. You can’t analyze it until you get it organized.

- The Solution: This layer performs critical functions like data normalization (let’s convert all those temperature readings to Celsius), creating a single data model, and combining streams of data so they make sense together.

You can think of this layer as a universal translator and an expert organizer for your data. It’s what prepares the data for business applications, and it’s a core function of most major IIoT platforms, a market valued at around $23 billion in 2024.

6. The Application of Insight: Putting Data to Work

The application layer is where that beautifully abstracted data is finally used by software to generate real business value.

This is the part of the IIoT architecture your team will actually see and interact with every day. It’s the software that turns a stream of numbers into actionable intelligence.

- Monitoring & Control: This includes the dashboards that show real-time asset performance or the interfaces that allow an operator to remotely adjust a piece of equipment.

- Analysis & Optimization: Here you’ll find applications for things like predictive maintenance, which can cut maintenance costs by 30-50% compared to old-school schedules. These apps can also find ways to optimize a whole production process for better efficiency.

- Integration: This layer provides APIs that allow IIoT data to be fed into other critical business systems, like an Enterprise Resource Planning (ERP) or a Manufacturing Execution System (MES).

This is truly where the return on investment for an industrial IoT project becomes tangible. It’s the difference between just collecting data and using data to make better, faster decisions.

7. The Business Interface: Connecting to the Enterprise

This top layer dictates how end-users and other business processes interact with the insights generated by the entire IIoT stack.

So, if the application layer is the software doing the work, what’s this? This final layer is focused on the presentation and integration of that work into the day-to-day rhythm of the business.

- User Collaboration: This is your people. It’s the plant manager getting an alert on her phone, the technician looking at a maintenance report on a tablet, and the executive team reviewing an efficiency dashboard.

- Process Integration: Here, the system itself takes action. A great example is an automated workflow that generates a maintenance work order in the company’s ERP system the moment the predictive analytics application flags a potential machine failure. It closes the loop between insight and action.

Fully integrated systems at this level are showing impressive results, with some companies seeing an 18% improvement in Overall Equipment Effectiveness (OEE) within three years.

The Security Mandate: A Concern for Every Layer

It’s tempting to ask, “Okay, but which layer is the security layer?” The answer is, they all are. Security in an IIoT architecture isn’t a single layer you can just add on top; it’s a cross-cutting concern that has to be architected into the system from the ground up. You simply can’t afford to have it any other way.

This means having device-level authentication at the Physical Layer, network encryption at the Connectivity Layer, secure access controls at the Application Layer, and a robust defense strategy for your cloud infrastructure. It’s a comprehensive effort, which is why cybersecurity spending for IIoT rose by 20% year-over-year in 2025. It’s a non-negotiable part of building a trustworthy system.

Building the Integrated Whole

At the end of the day, these IIoT architecture layers are not isolated silos. They are part of an integrated, end-to-end system where each layer depends on the one below it. The real value of an industrial IoT system comes from that seamless flow of data and control, all the way from a single sensor on the factory floor to a critical business insight in the boardroom. Having a well-defined architecture isn’t just a technical exercise; it’s the blueprint for turning that powerful vision into a reality.

FAQ

What is an Edge Gateway?

The brain of the edge layer is typically an Edge Gateway or a dedicated edge computing device. These are small, powerful computers that sit between the sensors and the wider network.

Why is edge computing important in IIoT?

It dramatically reduces latency, lowers data transmission costs by sending only what’s important, and allows a system to keep running even if its connection to the cloud goes down.

What is the role of the IIoT application layer?

The application layer is where abstracted data is finally used by software to generate real business value through monitoring, control, analysis, and optimization.