Key Takeaways

- The primary security goals for Industrial IoT (IIoT) and Operational Technology (OT) are safety and availability, differing from the confidentiality focus of Information Technology (IT).

- Integrating legacy OT equipment, which was not designed for internet connectivity, with modern networks is a major source of vulnerability.

- Effective IIoT security relies on a multi-layered strategy, including network segmentation, rigorous device lifecycle management, and IIoT-aware monitoring platforms.

- Solutions must address the entire ecosystem, from patching schedules and access control to supply chain verification and physical device security.

- Securing IIoT is a continuous process that directly impacts business-critical outcomes like uptime, quality, and worker safety, making it a strategic imperative rather than just a technical task.

Table of Contents

Introduction: The Promise and Peril of IIoT

We wired up our plants to run smarter, faster, and cheaper. That payoff is real. Yet every sensor and gateway also cracks the door open to real‑world risk across lines that move steel, water, gas, and power. This is a core business issue, not a side quest for IT. If we want uptime and safety, we need to face the Security challenges in IIoT like grown‑ups and build controls that respect the factory floor.

The Great Divide: Information Technology vs. Operational Technology

In IT, the crown jewels are data. In OT and industrial IoT, the crown jewels are people and uptime. You protect different things, so your playbook needs to shift.

- IT Security Goals: Confidentiality, Integrity, Availability.

- OT and IIoT Security Goals: Safety, Availability, Integrity.

IT vs. OT System Priorities

| Property | IT System | OT and IIoT System |

|---|---|---|

| Primary Concern | Protect data. | Protect people and process. |

| System Uptime | High, but windows are fine. | Nonstop, 24 by 7 by 365. |

| Patching Approach | Patch fast. | Patch in planned maintenance windows. |

Top 8 IIoT Security Challenges and Solutions

Now let’s talk about the Security challenges in IIoT you actually see in 2025 and how to beat them with real‑world moves that work on the plant floor.

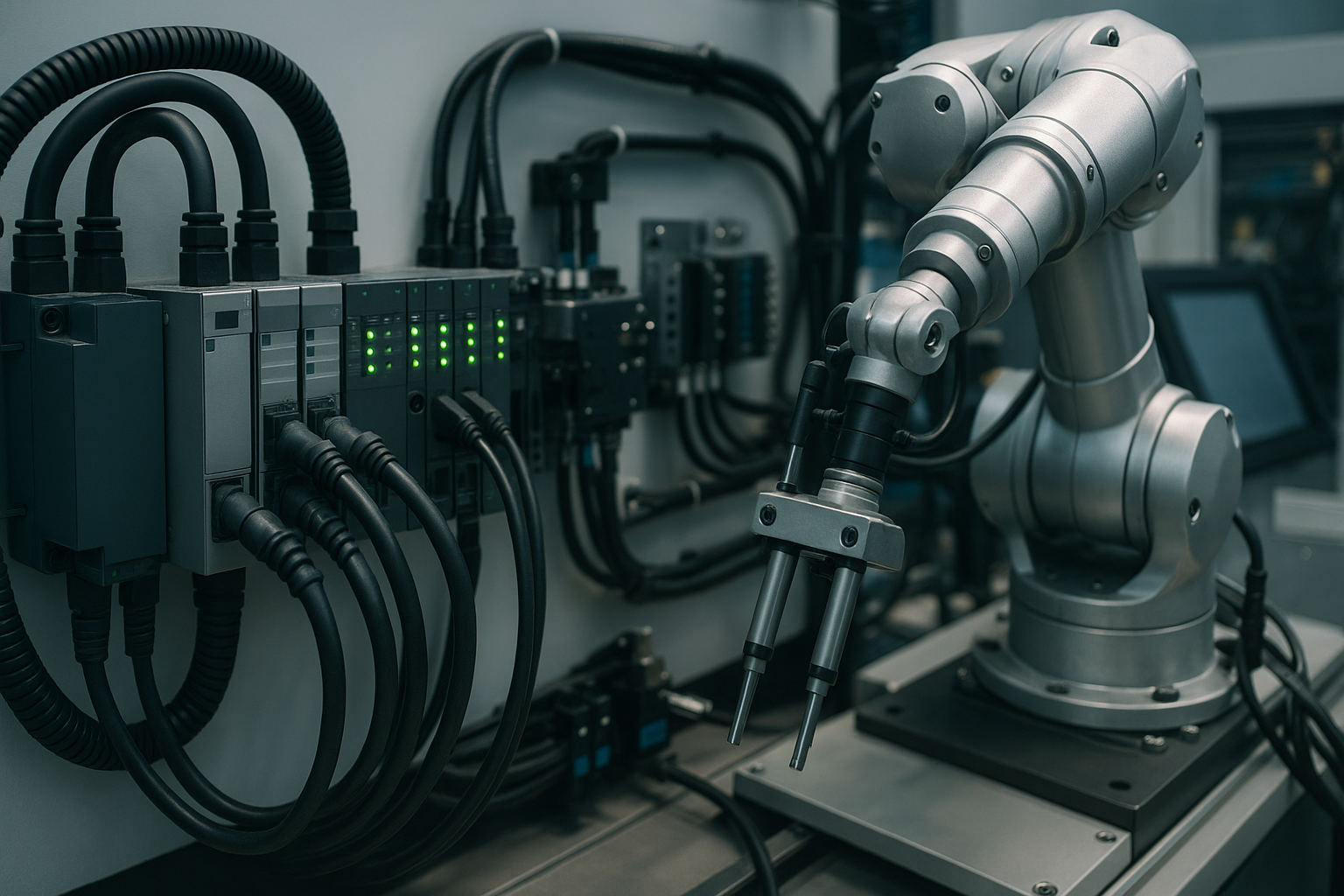

1) The Legacy Barrier: Integrating Aging OT with Modern Networks

Hooking decades‑old controllers to the internet invites trouble, since they were never built for security.

- Many run on unsupported operating systems and ship without encryption or modern auth.

- Patching can stop production, so updates stall for months.

A single unpatched controller helped an attacker pivot into a production cell and force an hours‑long outage in 2024.

Solution: Network Segmentation and Shielding

- Isolate OT from corporate IT and the internet with firewalls and a DMZ. Use strict allow‑lists between Purdue Model levels to contain incidents.

- Use intrusion prevention for virtual patching when you cannot update firmware. Block known exploits at the network edge and at cell zones.

2) The Endpoint Exposure: Insecure‑by‑Design IIoT Devices

A lot of sensors and actuators ship with weak or default credentials and no clean path to update.

- Default passwords and hardcoded creds are still common.

- No secure boot or firmware signing means attackers can load tampered code.

- Device identity is often weak, so spoofing is easy.

Solution: Rigorous Device Lifecycle Management

- Make password changes mandatory at install. Shut off unused services and ports on day one.

- Buy from vendors with a public disclosure process, signed firmware, and a clear update roadmap. Track end of support dates in your asset list.

3) The Protocol Problem: Unencrypted Industrial Communications

Old protocols were built for speed on isolated networks, not modern threats. They often send commands in clear text.

- Common examples: Modbus, DNP3, Profinet.

- Attackers can sniff traffic, steal creds, or alter commands with a man‑in‑the‑middle hop.

Solution: Secure Protocol Encapsulation and Gateways

- Wrap legacy traffic with TLS or IPsec to encrypt data without ripping and replacing hardware.

- Drop in protocol‑aware gateways that validate command structure and block unsafe writes or out‑of‑range setpoints.

4) The Access Blindspot: Insufficient Identity and Access Management

Loose permissions let intruders move laterally across lines and cells.

- Shared accounts break least‑privilege and create no‑blame audit trails.

- Former employees and third party vendor accounts hang around for months.

Solution: Role Based Access Control and MFA

- Map roles to job tasks. Give users and devices only what they need for work on that line or asset.

- Turn on multi factor for remote access and for any human interface to critical controllers.

5) The Visibility Gap: A Lack of Comprehensive Monitoring

If you cannot see plant traffic and device behavior, you cannot spot weird activity or respond fast.

- Traditional IT tools do not read OT protocols or state changes.

- Building a baseline in a complex plant takes time, so many teams fly blind.

Solution: Deploy an IIoT Aware Security Monitoring Platform

- Use passive network monitoring with deep packet inspection for industrial protocols. No active scans that knock devices offline.

- Turn on anomaly detection and automated alerting. Feed alerts to your SOC with context like Purdue level, asset owner, and process impact.

6) The Supply Chain Contagion: Compromised Components and Software

Weakness can land in your plant before you even rack the gear.

- Counterfeit parts and backdoored chips show up in gray channels.

- Third party libraries hide known bugs that never get patched.

Solution: A Software Bill of Materials and Vendor Audits

- Require an SBOM so you know every component in the stack. Track CVEs across that list.

- Build a vendor security review into procurement. Ask for disclosure timelines, update SLAs, and secure development practices.

7) The Physical Dimension: Unsecured Device Access

A simple cable in the wrong port can kick off a cyber mess.

- An attacker can plant a tiny computer on an open USB port or empty network jack.

- Stolen devices get cloned or tampered with offsite.

Solution: Integrating Physical Security and Cybersecurity Policies

- Lock network cabinets. Turn on switch port security and disable unused jacks.

- Train staff to report tailgating, missing gear, and odd dongles. Treat floor access the same way you treat remote access.

8) The Data Dilemma: Ensuring Integrity and Privacy

IIoT runs on data and also produces sensitive data, so you must keep it correct and protected.

- If someone alters sensor values, you can trigger unsafe states or damage equipment.

- Production data and recipes are trade secrets. Theft hurts revenue and valuations.

Solution: End to End Encryption and Data Validation

- Encrypt data in transit and at rest. Protect the historian and the cloud bucket holding years of runs.

- Add validity checks, sequence numbers, and integrity monitoring so you can flag spoofed readings or altered commands fast.

IIoT Security by the Numbers (2025)

| Statistic | Value | Context |

|---|---|---|

| IoT Device Growth | 35.2 billion+ | Total connected devices in 2025, with IIoT comprising a significant portion. |

| Daily Hacking Attempts | ~820,000 | Per day on IoT devices, a 46% increase over 2024. |

| Industrial Ransomware Incidents | 2,472 in Q1 | A 46% rise against industrial operators in early 2025. |

| Cost Per Incident | $4.97 million (avg) | Losses can range from $5 to $10 million in some sectors. |

| Average Downtime | 52+ hours | Per major cybersecurity event in an industrial setting. |

| Vulnerable Devices | Over 50% | Percentage of IoT gear shipping with critical flaws. |

| Blast Radius Reduction | Over 60% | Achievable with proper network segmentation and zoning. |

Quick Map to the Purdue Model

Why 2025 feels different:

- Connected devices hit 35.2 billion in 2025, with 40 billion forecast by 2030. IIoT makes up about 17 to 19.8 billion today.

- One provider blocked 629 million attacks in Q1 2025 alone.

- IoT devices face about 820,000 hacking attempts every day this year. That is a 46 percent jump over 2024.

- Ransomware against industrial operators rose 46 percent in early 2025, with 2,472 incidents in Q1.

- Manufacturing pays about 4.97 million dollars per serious incident. In some sectors, losses range from 5 to 10 million.

- Average downtime tops 52 hours per major event.

- Over 50 percent of IoT gear ships with critical flaws at any given time.

- Automated scans for default creds rose 16.7 percent worldwide in 2025.

- Shadow devices can be 30 percent of the fleet without anyone knowing.

What actually works, in numbers:

- Automated vulnerability scans and workflows cut remediation time by 30 to 50 percent.

- Real segmentation and zoning can trim blast radius by more than 60 percent during incidents.

Quick map to the Purdue Model:

- Keep Level 0 to 2 controls tight, with minimal inbound paths.

- Gate traffic at Level 3 with strict allow‑lists and protocol inspection.

- Only send what you must to Level 4 and 5, ideally through a broker with logging.

How to Address Security Challenges in IIoT

How to keep the Security challenges in IIoT from running you:

- Start with asset discovery across every line and site. You cannot protect what you cannot see.

- Set a patching plan with maintenance windows. Use virtual patching for legacy gear until you can update.

- Clean up identity and access across users and devices. No shared accounts. Rotate creds on a schedule.

- Encrypt legacy protocols with overlays. Add gateways that understand OT commands.

- Blend physical security with cyber checks. Locks and logs belong together.

- Track SBOMs and vendor performance like you track quality.

From Tactical Defense to Strategic Resilience

Why repeat this phrase? Because the Security challenges in IIoT are not static. New lines spin up. New devices land every week. New playbooks spread in attacker crews. When you talk about IIoT security challenges with your board, explain the uptime and safety angle first. Tie each dollar to fewer minutes of downtime. That lands.

This is not a one and done project. The IIoT security challenges shift every quarter, so your program has to breathe and move. When you nail the basics and keep improving, cybersecurity stops feeling like a cost and starts acting like a force multiplier for uptime, quality, and safety. If you are planning new industrial IoT rollouts, build security into the design from day zero. That way you stay fast, safe, and ahead next quarter and next year.

Frequently Asked Questions

What is the main difference between IT and OT security?

IT security prioritizes the Confidentiality, Integrity, and Availability of data. In contrast, OT and IIoT security prioritize Safety, Availability, and Integrity, focusing on protecting people, physical processes, and system uptime.

Why is patching legacy OT systems so difficult?

Patching can halt production, so updates are often delayed for planned maintenance windows that may be months apart. Furthermore, many legacy controllers run on unsupported operating systems and were never designed for modern security threats, making them inherently vulnerable.

What is the best first step to improve IIoT security?

The best first step is comprehensive asset discovery. You cannot protect what you cannot see, so identifying and inventorying every connected device across all plant lines and sites is a foundational requirement for any security program.

How can you secure devices that are insecure by design?

Implement rigorous device lifecycle management. This includes mandating password changes at installation, disabling all unused ports and services, and purchasing only from vendors that offer signed firmware, have a public vulnerability disclosure process, and provide a clear update roadmap.