How 3D Printing is Revolutionizing Mechanical Engineering Design

Estimated reading time: 10 minutes

Key Takeaways

- 3D printing fundamentally changes how products are designed and manufactured

- Technology has evolved from simple prototyping to full production capabilities

- Key technologies include FDM, SLA, SLS, and DMLS with different applications

- Eliminates traditional design constraints enabling previously impossible geometries

- New materials continue to expand possibilities for functional components

- Applications span aerospace, automotive, medical, and more industries

- Specialized software and digital workflows optimize the design process

- Understanding challenges and limitations is crucial for effective implementation

Table of contents

- Introduction

- Evolution of 3D Printing in Mechanical Engineering

- Fundamental 3D Printing Technologies for Mechanical Engineers

- Design Principles Transformation

- Material Innovations

- Practical Applications in Mechanical Engineering

- Design Software and Digital Workflow

- Challenges and Limitations

- Future Directions

- Conclusion

- FAQ

Introduction

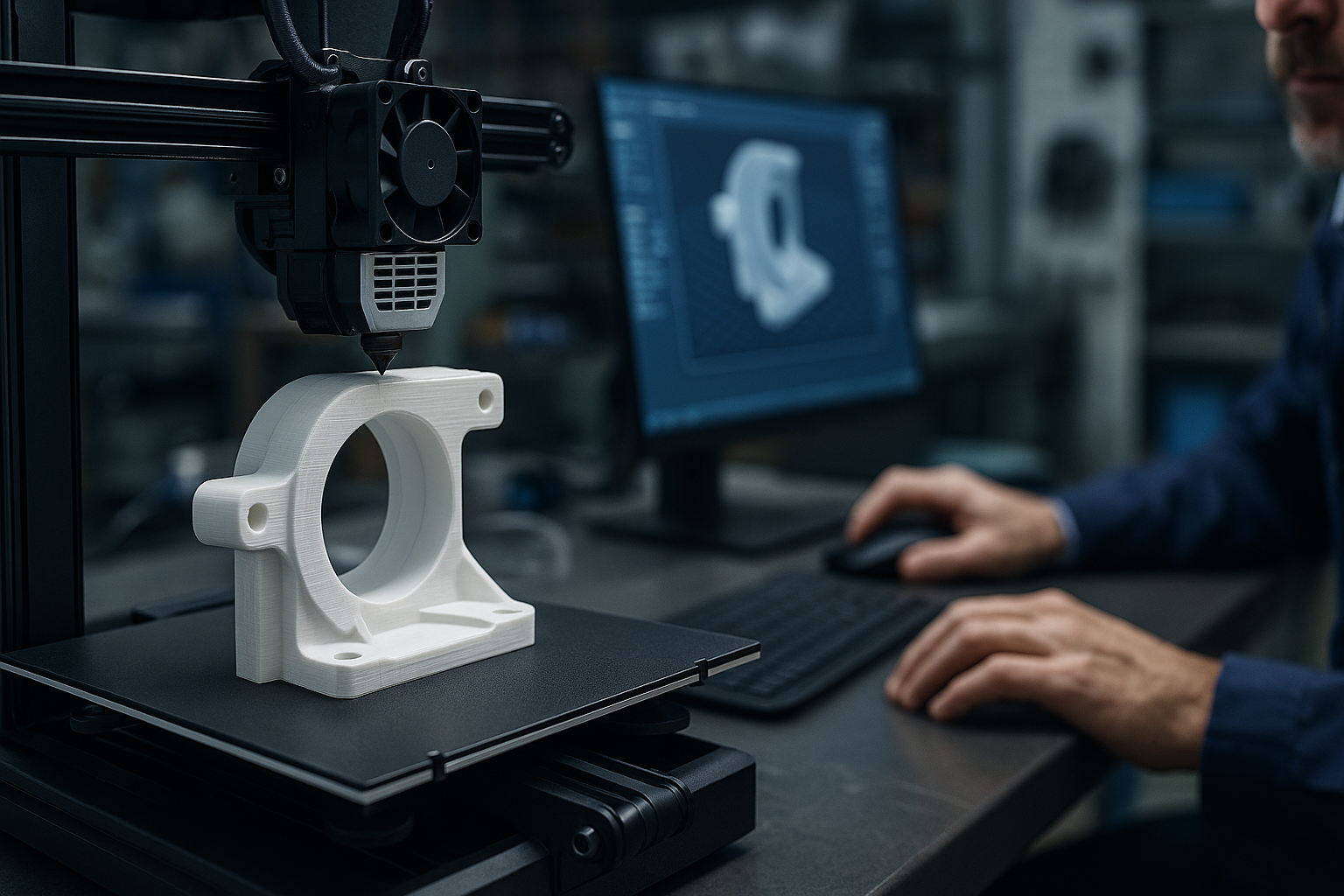

3D printing is transforming mechanical engineering by fundamentally changing how products are designed and manufactured. This technology, also known as additive manufacturing, builds objects layer by layer from digital models—a stark contrast to traditional manufacturing methods that carve away material. The shift enables mechanical engineers to design without many traditional constraints, creating components that were previously impossible to produce. Far from being optional knowledge, 3D printing has become essential for current and future mechanical engineers across industries.

Evolution of 3D Printing in Mechanical Engineering

3D printing’s journey in mechanical engineering spans four decades:

- 1980s: Stereolithography (SLA) invented by Chuck Hull

- 1990s: Introduction of Fused Deposition Modeling (FDM)

- 2000s: Metal printing technologies like Direct Metal Laser Sintering emerge

- 2010s: Widespread adoption in aerospace, automotive, and medical fields

- Present day: Full integration into standard mechanical engineering workflows

What began as a tool for creating simple prototypes has evolved into a manufacturing method capable of producing complex, functional parts. Early limitations in materials and precision have been largely overcome, making 3D printing vital rather than supplementary for engineering teams.

Fundamental 3D Printing Technologies for Mechanical Engineers

Four key technologies dominate mechanical engineering applications:

| Technology | Process | Materials | Precision | Applications |

|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | Extrusion of thermoplastic filament | PLA, ABS, PETG, Nylon | ±0.15mm | Functional prototypes, fixtures |

| Stereolithography (SLA) | Photopolymerization | Photopolymer resins | 25 microns | Detailed components, precision parts |

| Selective Laser Sintering (SLS) | Powder bed fusion | Nylon, polyamide | ±0.1mm | Complex assemblies, no support structures |

| Direct Metal Laser Sintering (DMLS) | Metal powder fusion | Stainless steel, aluminum, titanium | ±0.05mm | High-performance parts, heat-resistant components |

Each technology offers unique advantages for specific mechanical engineering applications, with selections based on required resolution, strength, production speed, and budget constraints.

Design Principles Transformation

3D printing has revolutionized mechanical engineering design principles:

Traditional constraints eliminated:

- No draft angles required

- Tool access no longer limits geometry

- Variable wall thickness possible in single parts

New capabilities enabled:

- Internal features and channels that were impossible to machine

- Part consolidation reducing assembly time by up to 80%

- Complex geometries with optimized performance

Topology optimization has become central to 3D printing design—this mathematical approach places material only where needed for structural integrity, creating components that are 30-50% lighter while maintaining strength.

Generative design takes this further by using AI algorithms to create multiple design solutions based on specified constraints. These computer-generated designs often feature organic, nature-inspired forms that would be impossible to manufacture traditionally.

Material Innovations

New materials specifically developed for 3D printing include:

- Advanced polymers like PEEK and ULTEM with heat resistance up to 260°C and tensile strengths comparable to aluminum

- Specialized metal alloys with properties optimized for layer-by-layer building

- Composite materials combining plastic matrices with carbon or glass fiber reinforcement

Metal 3D printing continues to advance with improvements in:

- Surface finish quality

- Dimensional accuracy

- Reduced porosity

- Expanded material options including tool steels and superalloys

Multi-material printing now allows single components to feature:

- Gradient properties that transition from rigid to flexible

- Embedded functional elements

- Varying mechanical characteristics throughout a part

Practical Applications in Mechanical Engineering

Real-world applications demonstrate 3D printing’s impact:

Aerospace: GE’s fuel nozzles consolidated 20 parts into a single component, resulting in a design that’s 25% lighter and 5x more durable.

Automotive: Bugatti developed titanium brake calipers that are 40% lighter than traditional aluminum versions while maintaining strength.

Medical: Custom prosthetics and implants now match the mechanical properties of human tissue, improving compatibility and comfort.

3D printing has transformed prototyping by:

- Cutting development cycles from weeks to days

- Enabling functional testing with final production materials IoT prototyping device testing guide

- Reducing development costs by 50-80%

For production, benefits include:

- Cost-effective small batch manufacturing

- Mass customization capabilities

- Simplified supply chains through on-demand production

Design Software and Digital Workflow

Specialized software tools have emerged to support additive manufacturing:

- Generative design programs like Autodesk Fusion 360 and nTopology

- Topology optimization tools including Altair solidThinking and ANSYS

- Simulation software adapted for 3D printed part analysis

The digital workflow for 3D printing involves:

- Creating models using parametric or direct modeling approaches

- Running simulations that account for anisotropic properties

- Converting designs to printable file formats (STL, 3MF, AMF)

- Setting slicing parameters that define mechanical properties

- Digital inventory management for on-demand production Multi-agent systems guide enterprise AI

Challenges and Limitations

Despite its advantages, 3D printing faces several limitations:

Technical constraints:

- Build volume restrictions (typically under 1m³)

- Surface finish issues requiring post-processing

- Directional strength characteristics based on layer orientation

- Batch-to-batch material property variations

Quality control concerns:

- Need for in-process monitoring systems

- Specialized inspection methods for complex internal geometries

- Certification challenges for critical components

Cost considerations:

- Break-even point typically between 500-5000 units

- Material costs 5-10x higher than traditional manufacturing

- Significant equipment and maintenance expenses

Workflow integration:

- Resistance to changing established design methodologies

- Software compatibility issues between tools

- New validation procedures required

Future Directions

3D printing in mechanical engineering continues to evolve through:

- Process innovations like Continuous Liquid Interface Production (CLIP) for faster printing

- Hybrid systems combining additive and subtractive techniques

- AI integration for design optimization and process control AI trends navigating future

- New materials including programmable and self-healing options

Research is advancing:

- Process monitoring for real-time quality control

- More accurate simulation capabilities

- Sustainable practices including material recycling

Educational institutions are responding with:

- Updated engineering curricula

- Industry partnerships focused on additive manufacturing

- New teaching resources reflecting current technology

The future points toward:

- Distributed manufacturing networks

- Digitized supply chains

- Standard customization practices

- Integration with Internet of Things and digital twins

Conclusion

3D printing has redefined mechanical engineering design by:

- Removing traditional manufacturing limitations

- Enabling material use optimization

- Blurring the line between design and manufacturing

- Making customization economically viable

For mechanical engineers looking to embrace additive manufacturing, key steps include:

- Understanding Design for Additive Manufacturing principles

- Identifying suitable applications based on each technology’s strengths and limitations

- Investing in education and training

- Starting with prototyping before moving to end-use parts

The technology continues to mature rapidly, making ongoing education essential. Engineers who master these new approaches will lead innovation across industries, creating designs that were previously thought impossible.

FAQ

Q1: What are the main 3D printing technologies used in mechanical engineering?

A1: The four primary technologies are Fused Deposition Modeling (FDM) for functional prototypes, Stereolithography (SLA) for detailed components, Selective Laser Sintering (SLS) for complex assemblies, and Direct Metal Laser Sintering (DMLS) for high-performance metal parts.

Q2: How does 3D printing change design principles for mechanical engineers?

A2: 3D printing eliminates traditional constraints like draft angles and tool access limitations. It enables internal features, complex geometries, and part consolidation that would be impossible with conventional manufacturing. Topology optimization and generative design are now central to creating lighter, stronger components.

Q3: What materials can be used in 3D printing for mechanical applications?

A3: Materials range from standard plastics (PLA, ABS) to advanced polymers (PEEK, ULTEM), specialized metal alloys (stainless steel, titanium, aluminum), and composites with fiber reinforcement. Multi-material printing allows combining different properties within a single component.

Q4: What are the key limitations of 3D printing technology?

A4: Limitations include build volume restrictions, surface finish issues requiring post-processing, directional strength characteristics, quality control challenges, higher material costs, and the need for specialized inspection methods for complex geometries.

Q5: How can mechanical engineers incorporate 3D printing into their workflow?

A5: Engineers should start by understanding Design for Additive Manufacturing principles, using specialized software tools for generative design and topology optimization, identifying suitable applications based on technology strengths, and beginning with prototyping before moving to end-use parts.