Estimated reading time: 6 minutes

Key Takeaways

- Engineering design automation (EDA) uses software and AI to automate design, testing, and production.

- EDA reduces design cycle time by 30-70% and dramatically lowers errors.

- AI in design empowers generative design and predictive performance modeling.

- CAD automation streamlines repetitive tasks and improves data consistency.

- Automated testing accelerates verification from simulation to physical prototypes.

- RPA and manufacturing automation connect design closer to production, improving quality and throughput.

- Successful implementation requires staged adoption, strong governance, and continuous measurement of KPIs.

Table of contents

Engineering design automation is transforming how products move from concept to reality. By using software, rule-based systems, and artificial intelligence to automate engineering processes throughout the product lifecycle, companies are achieving unprecedented efficiency. This approach forms the backbone of modern engineering strategies, connecting AI in design, CAD automation, automated testing, and manufacturing systems into a cohesive workflow that delivers measurable business impact.

What is Engineering Design Automation?

Engineering design automation (EDA) applies software-driven rule-based systems, parametric templates, and workflow orchestration to automate repetitive engineering tasks across the product development process. Unlike broader engineering automation, EDA focuses specifically on generating, verifying, and optimizing digital design data.

The core components include:

- Rule-based design: Encoding engineering rules to ensure compliance

- Parametric templates: Predefined models that adapt to input parameters

- Generative design: Using algorithms to explore design spaces

- Simulation-driven optimization: Automating digital prototype evaluation

- Workflow orchestration: Coordinating processes across engineering tools

These capabilities deliver significant benefits:

| Benefit | Impact |

|---|---|

| Speed & Efficiency | 30-70% reduction in design cycle time |

| Consistency | Dramatic reduction in design errors |

| Cost Reduction | Lower labor requirements and rework |

| Traceability | Enhanced auditability and compliance |

| Scalability | Efficient handling of complex configurations |

These benefits highlight how EDA empowers businesses with greater agility and cost-effectiveness.

AI in Design

AI in engineering design applies machine learning techniques to enhance the design process, enabling more innovative and efficient product development. Key applications include:

- Generative design for creating optimized geometries

- Design space exploration using neural networks to discover novel solutions

- Predictive performance modeling leveraging historical simulation data

- AI copilots within CAD tools offering real-time suggestions

For these systems to work effectively, companies need large, labeled datasets from historical CAD/CAE work and continuous validation loops to ensure AI models accurately reflect physics and business requirements. This continuous input is vital for maintaining accuracy.

While AI can automatically propose lightweight structures subject to strength constraints, results must be validated via physics-based simulation to avoid “hallucinations” or unphysical solutions.

This careful validation ensures that AI-driven designs remain grounded in reality.

CAD Automation

CAD automation systematically applies rules, scripts, and parametric methods to streamline repetitive tasks within design software. Key components include:

- Parametric modeling standards and feature libraries

- Design rules capture for compliance checking

- Macros, scripts, and API automation for batch operations

Organizations implementing CAD automation see fewer manual errors, faster engineering change order cycles, and the ability to handle more complex product configurations without proportional increases in design effort.

Specific applications include automated drawing generation, automatic application of standard features, batch processing for similar components, and automated generation of manufacturing data from design models.

This level of automation is critical for efficiency in modern product development.

Automated Testing

Automated testing in engineering applies software and hardware systems to perform verification without manual intervention. This spans from digital simulation to physical prototype testing. Such automation is vital for rigorous product development.

Design-stage test automation includes:

- Automated simulation test suites running hundreds of load cases

- Design of Experiments approaches exploring parameter spaces

- Surrogate modeling creating fast approximations of complex simulations

Physical test automation encompasses:

- Data acquisition scripts for collecting and analyzing test data

- Hardware-in-the-loop testing for control systems

- Automated test benches performing repetitive physical tests

These approaches mirror software engineering’s continuous integration/continuous deployment practices, reducing integration risk and accelerating development cycles.

Robotic Process Automation in Engineering

Robotic Process Automation (RPA) automates routine, rule-based administrative tasks within engineering workflows. Key applications include:

- BOM generation and management

- Metadata entry and document processing

- PLM and ERP synchronization

- Drawing release workflows

- Compliance documentation management

RPA addresses workflow handoffs but doesn’t replace engineering judgment. It works best with robust governance to avoid creating brittle processes that break with minor changes.

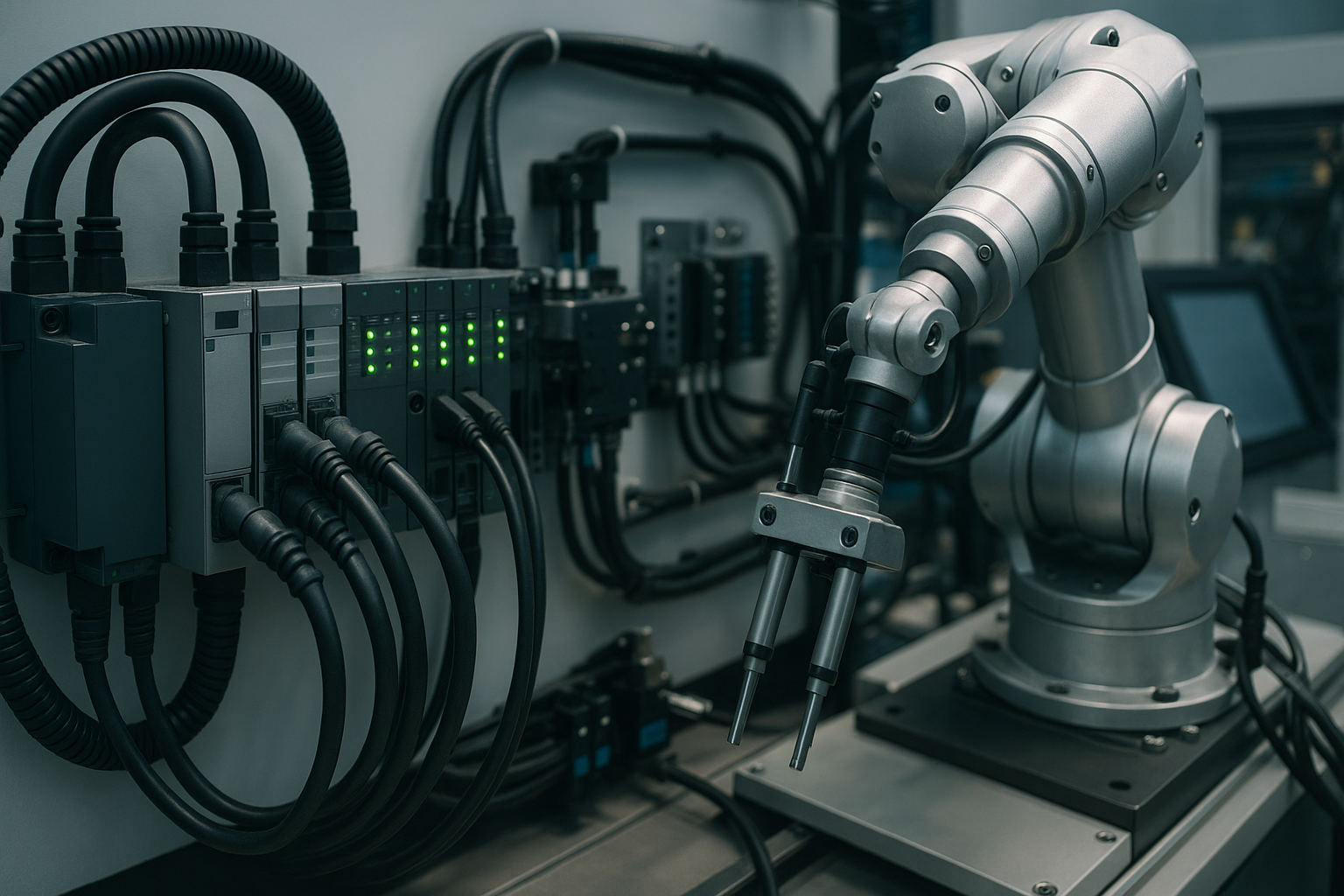

Manufacturing Automation

Manufacturing automation connects design directly to production through:

- Automated NC programming converting designs to machine instructions

- Robotic assembly cells adapting to different product configurations

- Automated inspection systems verifying quality against specifications

- Additive manufacturing workflows streamlining prototyping

The digital thread concept connects engineering systems directly to manufacturing execution systems, enabling automatic work instruction generation and closed-loop feedback from factory data for continuous improvement.

Benefits include quality improvements, throughput increases, reduced lead times, and the ability to handle higher product complexity without proportional cost increases.

Implementation Roadmap

Organizations can adopt a staged approach to engineering design automation:

- Pilot automation in CAD or simulation to establish proof of concept

- Expand with AI in design to enhance innovation

- Scale using RPA to streamline administrative processes

- Connect and automate manufacturing execution

When selecting projects, target high-variance, repetitive workflows where automation can provide immediate value and ensure sufficient data availability to support initiatives.

Change management considerations include:

- Investment in training and skills development

- Updates to engineering standards and processes

- Governance committees to oversee automation initiatives

- Communication strategies to address concerns

Effective change management is crucial for successful adoption.

Measuring Success

Organizations should track key performance indicators including:

- Engineering cycle time from concept to release

- First-pass yield and defect escape rate

- Engineering change order turnaround time

- Test coverage metrics

- Manufacturing throughput and on-time delivery

Establish performance baselines before automation and measure improvements after implementation using statistical techniques for validating results.

Real-World Examples

In the automotive industry, CAD automation for vehicle variant design has reduced engineering time by 40-60%, while simulation regression testing catches design issues earlier in the development process.

Aerospace companies apply AI-enabled lightweighting that reduces component mass while maintaining strength, and robotic inspection systems dramatically reduce quality verification time.

Industrial equipment manufacturers use RPA to synchronize product data between PLM and ERP systems, eliminating manual data entry, while digital thread implementations connect engineering to manufacturing for agile market response.

Future Outlook

The future of engineering design automation includes:

- AI copilots embedded in design platforms providing real-time guidance

- Autonomous optimization systems with human oversight for critical decisions

- Model-based enterprises with integrated digital representations

- Convergence of simulation, testing, and production data into self-improving systems

Organizations that embrace these technologies will gain significant competitive advantages through faster innovation cycles, higher quality products, and more efficient operations. This proactive approach positions them for future success.

Getting Started

To begin implementing engineering design automation:

- Assess current engineering processes for automation opportunities

- Start with well-defined, high-value use cases

- Focus on measuring and communicating results

- Build capabilities incrementally

- Invest in both technology and organizational change

By adopting a strategic approach to engineering design automation, organizations can transform their product development processes and create sustainable competitive advantages in increasingly complex markets.

This strategic approach is key to unlocking the full potential of EDA.

FAQ

Q1: What is the main goal of Engineering Design Automation?

A1: The main goal is to automate repetitive and complex engineering tasks throughout the product development lifecycle, enhancing efficiency, reducing errors, and accelerating time to market.

Q2: How does AI contribute to engineering design automation?

A2: AI contributes through generative design, design space exploration, predictive performance modeling, and AI copilots within CAD tools, enabling more innovative and optimized designs.

Q3: What are the key benefits of implementing EDA?

A3: Key benefits include a 30-70% reduction in design cycle time, dramatic reduction in design errors, lower costs, enhanced traceability, and improved scalability for complex configurations.

Q4: Is EDA only for large enterprises?

A4: While large enterprises often have vast resources, EDA can be scaled to benefit organizations of all sizes. Starting with pilot projects and high-value use cases makes it accessible to smaller businesses as well.

Q5: What challenges might arise during EDA implementation?

A5: Challenges can include the need for significant initial investment, data availability and quality issues, resistance to change from employees, and the complexity of integrating diverse engineering systems.